Key benefits

Key benefits Yield, capacity, and quality per operator Equal capacity per operator Custom designs Robust and hygienic equipment Own hardware and software

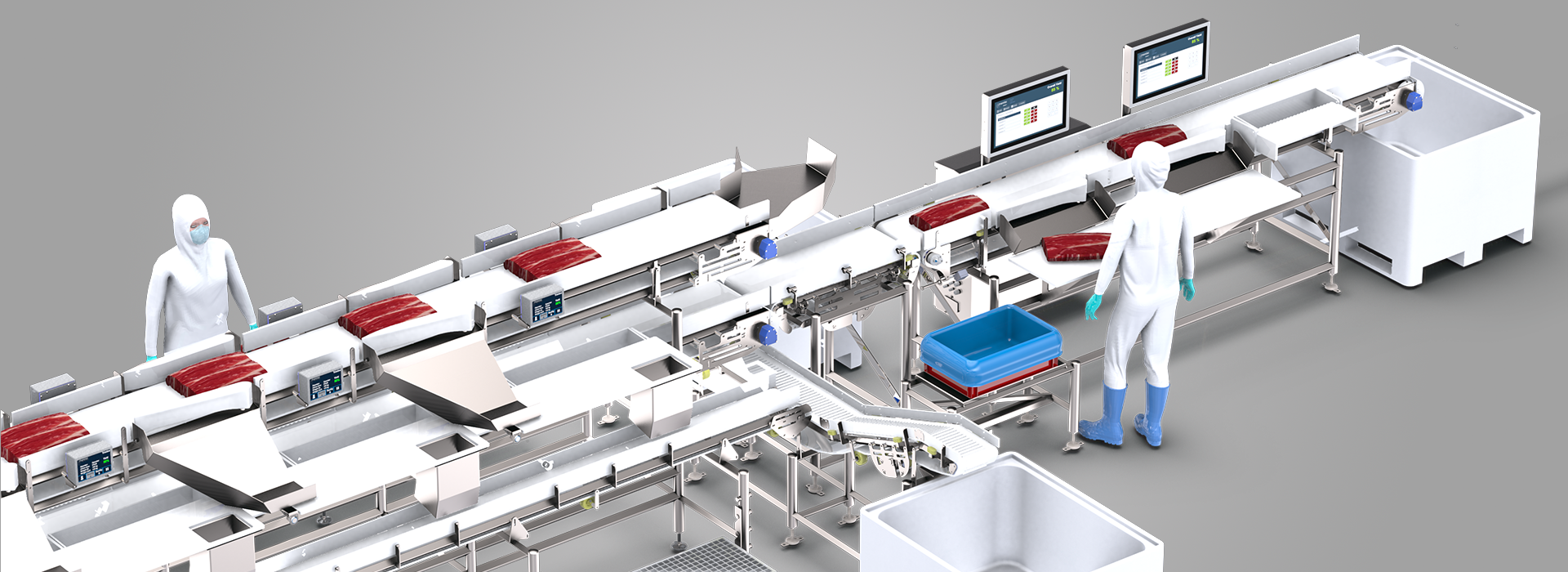

Factors such as yield, and capacity are crucial for the profitability of a meat processor. MARELEC has now developed an intelligent trimline which will monitor yield, capacity, and trim quality per operator.

By having this data available live during production, you can make adjustments where necessary, without losing valuable time.

An intelligent trimline also allows you to divide the incoming flow of raw material between the available operators. MATRIX will store all your processing data and allow you to make data-driven decisions.

v Yield, capacity, and trim quality per operator

You can access all valuable data can be accesed at any time. Key factors such as yield can be shown live to all of the operators. Our software package MATRIX also allows you to store this data and create daily, weekly, or monthly reports

40 years' experience

Our experienced team of engineers will work out an efficient solution depending on your needs. We realize that every plant is different and requires a specific approach. Marelec is big enough to cope but small enough to care!

Custom designs

MARELEC offers a wide range of tailor made solutions for the specific needs of each customer. MARELEC places a priority on openness with customers, in order to identify needs and fulfil expectations.

Robust and hygienic equipment

MARELEC systems have a completely open structure, for ease of cleaning and disinfection. The design of the graders avoids horizontal surfaces are avoided. All electrics and electronics are in fully sealed cabinets with a unique hygienic labyrinth double sealing. All materials used are FDA approved.

Own hardware and software

MARELEC Food Technologies designs and manufactures high-tech portioning, weighing, grading and trimline solutions. Our software package, MATRIX, keeps track of every single product that is being processed. This traceability is essential for high-quality producers who want to guarantee food safety for their FMCG customers.

Subject to modifications for technical progress