Key benefits

Key benefits Unparalleled accuracy High capacity Minimize human errors Robust and hygenic design Various infeed systems Integrated in turn-key solutions Easy connection with MATRIX software

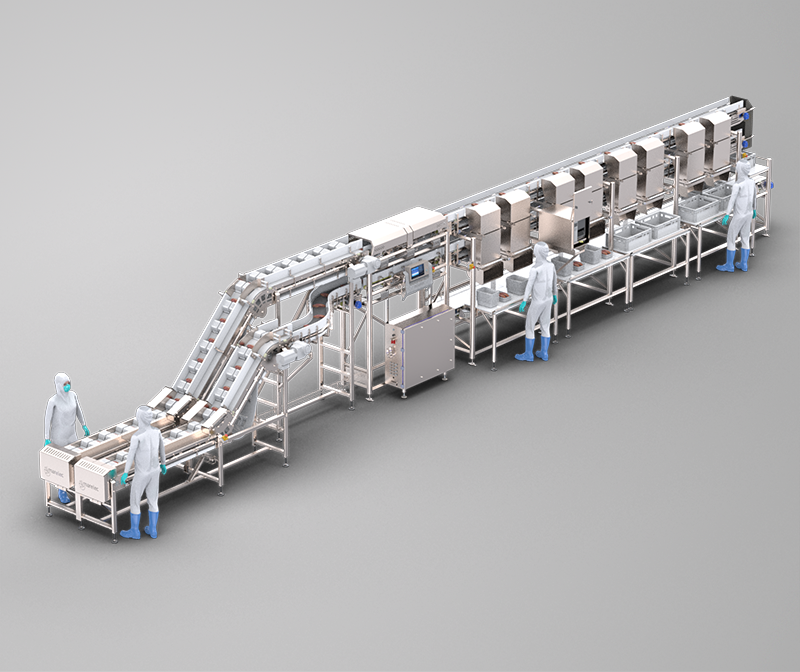

Breast caps or front halves often fall directly from the cut-up line onto an infeed system that ensures proper feeding towards the dynamic weighing section. This infeed ensures the correct distance between 2 products to guarantee fast and accurate weighing.

Specifications

Belt width: 254 to 300 mm / 10 to 12 inches Max. weight: up to 1,5 kg/ 3 lb Lanes: single or double - horizontal or vertical Multiple infeed systems Various label printing and software options

Ergonomic design

A team of engineers translates breast cap sorting and packing requirements into a custom grading solution. Full consideration is always given to the ergonomics for the operators. This flexible approach guarantees the perfect solution for the application while maintaining the maximum throughput as a priority with the smallest possible footprint.

Robust and hygenic design

The graders have a completely open structure, without hidden corners, for ease of cleaning and disinfection. The design of the grader avoids horizontal surfaces. Batching stations can be opened easily. All electrics and electronics are contained in a completely sealed cabinets with a unique hygienic labyrinth double sealing. All materials used are FDA approved. To avoid housings and reductors, all motors are silent stainless steel drum motors with IP 66 or higher protection.

Various infeed systems

The capacities will determine if a single or multiple sorting lane is needed.

Easy connection with MATRIX software

The interface is quick, user-friendly and intuitive to program. Over 100 programs can be stored. Production data can be viewed on the grader HMI. The user-friendly MATRIX program stores processing data on an office PC for traceability. MATRIX also allows the grader to be controlled remotely.

Subject to modifications for technical progress