Key benefits

Key benefits Unparalleled accuracy Optimum product handling Ergonomic, robust, and hygienic design Integrated in turnkey solutions Simple to operate Easy connection with MATRIX software Label printing and traceability options

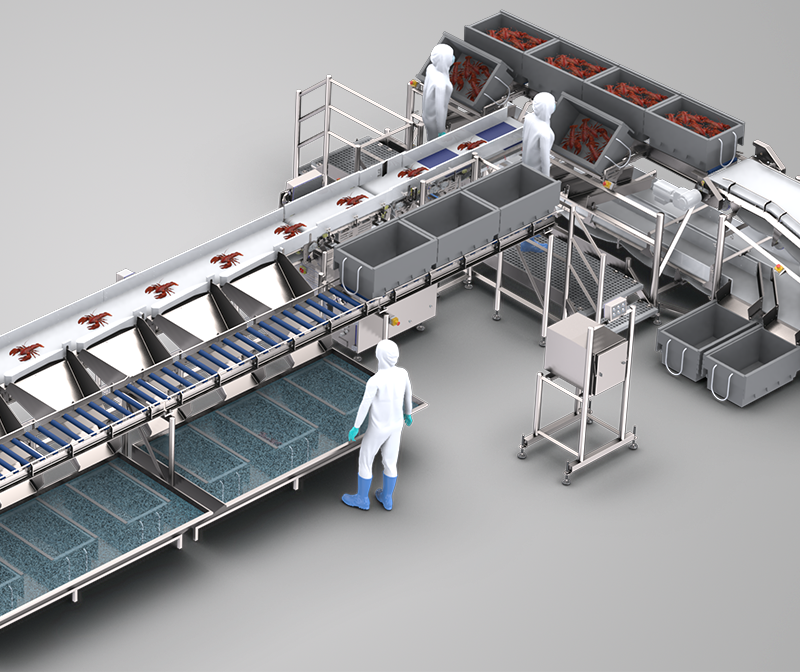

Not only do live lobsters or crabs vary in size, they also have different qualities. MARELEC's grading solutions are designed so as to optimize the ergonomics for operators, while always keeping the logistics flow in mind. Other shellfish such as Norwegian lobsters are smaller in size and require high-speed grading solutions.

Specifications

Belt width: 254 up to 450 mm / 10 up to 18 inches Max. weight: up to 6 kg/ 13 lb Max. length: up to 600 mm / 2 ft Max. capacity: 150 ppm Lanes: single or double Multiple infeed and sorting solutions Various label printing and software option

Product handling

Optimum product handling is the way to keep quality and capacity high. High-end products such as Norwegian lobsters can be small and require a high capacity to achieve a profitable volume. Special infeed and separation methods on the grader are the key to profit. Similar challenges occur with live lobster grading.

Ergonomic design

A team of engineers translates your sorting and packing requirements into a custom grading solution. Full consideration is always given to the ergonomics for the operators. This flexible approach guarantees the perfect solution for the application while maintaining the maximum throughput as a priority with the smallest possible footprint.

Robust and hygienic design

All graders have a completely open structure, with limited hidden corners, to optimize cleaning and disinfection. The design of the graders avoids horizontal surfaces. Batching stations can easily be opened for optimum hygiene. All electrics and electronics are in completely sealed cabinet with a unique hygienic labyrinth double sealing. All materials used are FDA approved. To avoid housings and reductors, all motors are silent stainless steel drum motors with IP 66 or higher protection.

Easy connection with MATRIX software

The interface is quick, user-friendly and intuitive to program. Over 100 programs can be stored. Production data can be viewed on the HMI grader. The user-friendly MATRIX program stores processing data on an office PC for traceability. In addition to full traceability, MATRIX CG will provide you with valuable KPIs to monitor and further control your process.

Subject to modifications for technical progress