Key benefits

Key benefits Unparalleled accuracy Optimized yields Intelligent cutting algorithms Modular design for increased capacity Extremely hygienic, easy to clean User friendly software interface

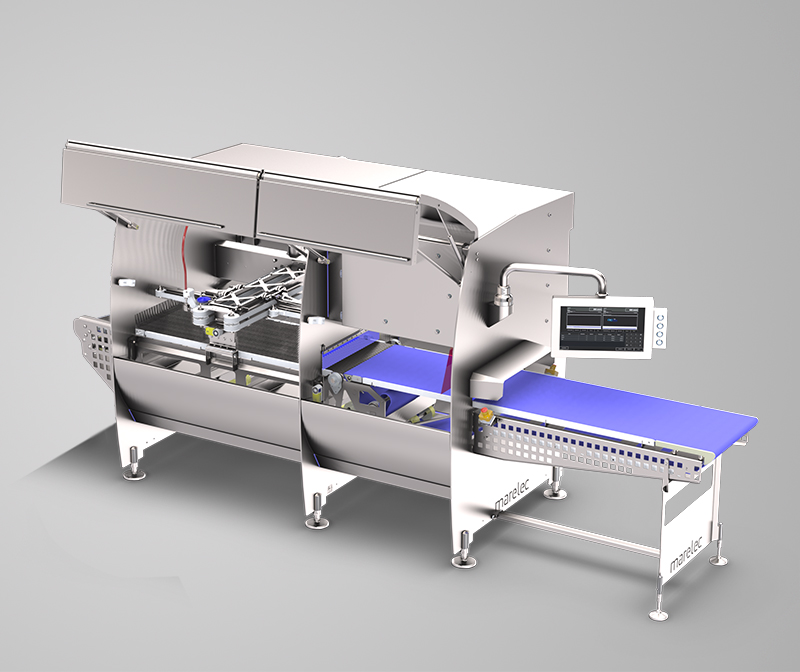

The PORTIO JET is developed to maximize yields when cutting predetermined shapes to fixed weights from fish fillets. The camera and laser combination scans to the highest accuracy and the intelligent cutting algorithm calculates the optimum cutting pattern. Typical applications include cutting salmon filets into fixed-weight loin portions, belly trim and tail section. By-products can be cut into strips and cubes. Whitefish fillets can also be portioned into several fixed-weight portions.

The MATRIX J software collects all production data from the PORTIO JET and allows it to generate production reports for each shift or program and to trace changes at machine level. MATRIX J software enables users to remotely take programs offline and monitor the status of the machine using an event log.

Specifications

Lanes: 1 / 2 Cameras: 2 top cameras Belt width: 600mm / 23.6 inches Max. product dimensions: 800 x 580 x 70 mm / 31.5 x 22.8 x 2.75 inches Maximum pressure: 3800 bar / optional 6000 bar Max. cutting rate: Depending on application and number of cutting stations

Unparalleled accuracy

The waterjet cutter PORTIO JET uses the latest vision technology. It features a 200Hz camera that scans the products such as salmon fillets or white fish fillets and converts them into a 3D model

Flexible cutting algorithms

Our portioning software marks the cuts which have priority over others and will determine the cutting pattern, so creating the most value.

Optimized yields

Combining the latest vision technology with our PORTIO JET optimalisation software and state-of-the-art nozzles results in the highest yield in the market.

Modular design for increased capacity

The base unit of our waterjet cutter consists of 1 scanning station and 2 high-pressure cutting heads and is called the PORTIO JET 2. Depending on your needs, the PORTIO JET 2 can be extended with series of 2 high-pressure waterjet stations, and up to a total of 8 cutting heads.

Extremely hygienic, easy to clean

The waterjet cutter complies with the most stringent hygiene standards. The open structure of the portioning machine for poultry allows it to be fully cleaned using a pressure washer and disinfected on the inside and outside. All cabinets with electrics and electronics have a unique drying system to prevent the build-up of condensation.

User-friendly software interface

Intuitive programming of cutting patterns and fast and easy fine-tuning of the programs to get the maximum yields. The cutting pattern is shown on the screen along with details of the thickness and the weight of each fish portion.

Subject to modifications for technical progress