Key benefits

Key benefits Real-time monitoring Remote control Reporting Maximize Yield Maximize Capacity Minimize Give-away Advanced Order Management Labelling Traceability Flexible software

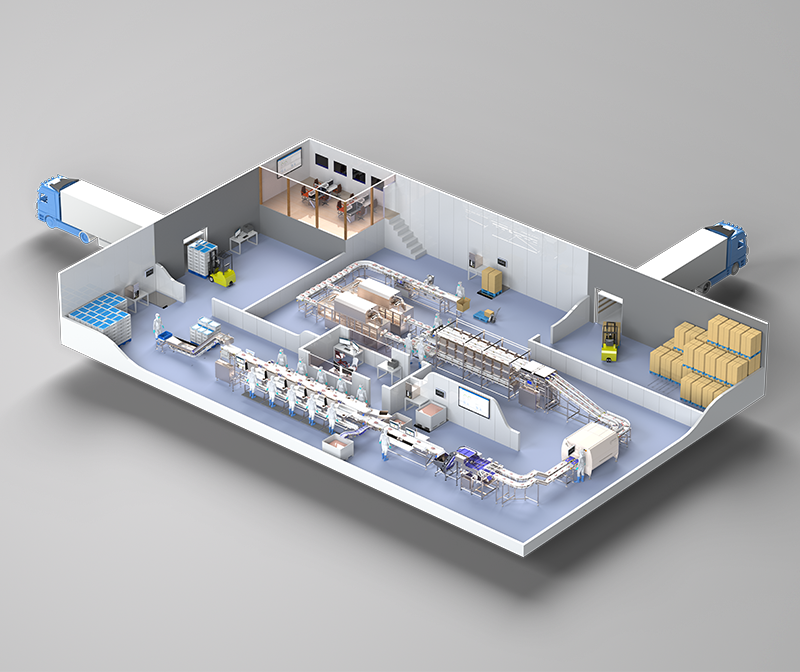

With the flexible and modular MATRIX Software, MARELEC offers Processing Solutions adapted to fit the individual needs of each customer. This ranges from production data for reporting from a stand-alone MARELEC device, to overall process monitoring and control of an entire food processing plant.

Food processing companies rely on data analysis to determine where improve their processes. This means that real-time monitoring and controlling of Key Performance Indicators (KPIs) such as yield, throughput, giveaway, quality, and uptime is crucial for the competitiveness and profitability of their business.

Receiving raw materials

Raw materials arrive at the plant. A bar code is attached and read before processing. This is the starting point for MATRIX to fully trace the goods.

Flow scale

One flow-scale weighs the flow of products before trimming and another flow-scale measures the flow after trimming. MATRIX monitors the yield by comparing the weights on both scales. By monitoring the yield, the Overall Equipment Efficiency can be determined, and machine settings can be fine-tuned to optimize production.

Trimming

Raw product is weighed before being assigned to an operator who will trim the product. By monitoring the weight of the trimmed end-product and the side-product, it is possible to individually evaluate operators for yield and throughput.

Portioning

Value is added by portioning products to fixed weights or producing multiple portions with individual higher values. With conditional programs, the intelligent Portion Cutter PORTIO always calculates portions for zero waste, without trimming, thus increasing yields and avoiding give-away. MATRIX keeps track of all portions produced and generates production reports showing yield and throughput.

Grading

The intelligent software in MARELEC graders ensures that batches are created at target weight with a minimum of give-away. This improves your profitability. MATRIX produces production reports with detailed information on all batches produced.

Automated batch discharge combined with the MATRIX Batch Tracking Device and labeler ensure traceability throughout the entire process.

Packing

MATRIX interfaces with 3rd party solutions to route batches or trays to the packing machines. MATRIX communicates in between devices so it stays fully in control and guarantees complete traceability throughout the process and manages the entire flow of the order.

Labeling

The MATRIX Label Manager is the ultimate tool for private labelling. It ranges from a single printer to complete inline print & apply solutions, ensuring transparent traceability.

The Advanced Order Processing & Planning Module enables MATRIX to automatically switch between orders and customize and print private labels when the order has been completed. MATRIX will prioritize orders on the fly to accomodate the flexibility expected by your customers and so you can deliver within the agreed delivery time.

Order picking & dispatch

MATRIX routes the packed product to the packing station for box packing and/or palletizing.

A customized human machine interface enables monitoring and adjustment of the order progression and assigned packing stations. Damaged a label? No problem. Reprint it on demand while packing!

Process control

Real-time data processing and remote control of your equipment from a centralized point. MATRIX allows you to monitor your entire process and to make on-the-fly adjustments with the quickest response time.

Order Processing and planning

By using MATRIX Advanced Order Processing in combination with the Planning Tool, MATRIX can be left unsupervised without worrying of overproduction. This creates valuable additional time to focus on other worthy aspects of the production management.

MATRIX lets you intelligently navigate your products through the process flow. Minimize handlings to ensure longer shelf life and prioritize orders to ensure that your customers get the right product at the right place at the right time. Subject to modifications for technical progress